wire edm machine working principle

Sometimes it is necessary to make a double jump if the distance between objects is large and one jump is not enough to overcome it. A Customizable Wire Electric Discharge Machine Inventors.

2D and 3D Device and Process Simulator.

. Examinations of numerous cases of machine parts broken under actual working conditions indicate that at least 80 per cent of these ruptures are caused by fatigue stresses. Electrical element In circuit theory a node at which some electrical property is concentrated resistance etc. To reconstitute this data on the receiving end expressions are used to compute missing links type information and other control data.

Since they seem to be a regular and recognized type of machine then there has to be at least a few tooling suppliers for them. Selection principle of stamping equipment. In the cutting process there are many parameters that affect the cutting quality and the conditions are complex sometimes the cutting results in the stratification and.

Hence to test materials for this class of stress the tests should be made to stress the. Separation or molding process. The total station is an electronic theodolite transit integrated with an electronic distance meter EDM plus internal data storage andor external data collector.

Most fatigue ruptures are caused by bending stresses and frequently by a revolving bending stress. It One common symptom of a faulty control solenoid is that your transmission may experience problems shifting gears. Compared with laser cutting plasma arc cutting wire electrode EDM and other methods there are shortcomings such as low feed rate and poor machining accuracy.

Combine the existing equipment conditions of the. Electrical equipment Apparatus for generation transmission or utilization of electric power. In Australia the EJ208 engine was introduced in the 2001 Subaru BE Liberty B4 which with a manual transmission produced peak outputs of 190 kW and 320 Nm.

2D Gel ElECTRO Phoresis with accessories. Now David says CNC has become a centerpiece of the shops productivity. It appears there a small part sheet metal and wire folding machine with some possible stamping or punch press capability for at least that light sheet metal.

There are many independent Android app developers out there who design code and test the apps they have been working on only to find out Anyone can sign up at SlideMe as a developer and can upload their Android apps for free. It is new process and. Then I pulled off another 10mm of the backing paper from the adhesive and repeated 30 times.

I raised the grinding head by about 10mm then walked behind the machine and used my fingertip to smooth down the tape which was hanging from the applicator under its own weight. This top free hacking tool was released a long time ago as a clientserver application. Divided by the technical principle.

There are several numbers of methods like traverse triangulation etc to provide these control. Kane Kamlesh Joshi Nitin Tiwari S. Existing solutions for human-machine interfaces are expensive and have yet to be available to the many.

Machine Tool Design Technology to offer Sodick EDM machines Machine Tool Design Technology has announced that the company has been appointed to market and distribute Sodick EDM products in South Africa. This fourslide machine is stamping wire loom holders an example of which is sitting on the lower die. From 2002 the BE Liberty B4 was offered with an automatic transmission for which the EJ208 engine was.

Email protected email protected. We have 76321 resumes in our database Showing all resumes. Browse movie times watch movie trailers find cinema deals and book your cinema tickets online today.

It was first observed in 1770 by Joseph Priestley. In fact it is a. He was an English physicist.

Tom and David have settled into a rhythm where the initial design and customer consultation is completed by Tom in the front office and then the part is programmed by David in BobCAD-CAM. 2500 kN Servo Hydraulic four column loading frame and controller of Universal Testing Machine UTM MTS 31141. Post a Resume Its Free.

Die sinking EDM consists of an electrode and the workpiece is submerged in an insulating liquid. Subarus EJ208 engine was a 20-litre horizontally-opposed petrol engine with sequential turbochargers. These expressions together with the data on the wire can be used by the client to compute predictable payload.

8c953 Wiring Diagram For Craftsman Riding Lawn Mower. Since I was working alone I did this in short cycles. Available on the Web Android and iPhone.

The tape was. The purpose of any survey is to prepare maps control points formed a basic requirement for the preparation of these maps. The machine uses the.

These structures reduce drag to the fluid flowing over them. Electronic music is music that employs electronic musical instruments digital instruments or circuitry-based music technology in its creation. Since they seem to be a regular and recognized type of machine then there has to be at least a few tooling suppliers for them.

It appears there a small part sheet metal and wire folding machine with some possible stamping or punch press capability for at least that light sheet metal. It includes both music made using electronic and electromechanical means electroacoustic musicPure electronic instruments depended entirely on circuitry-based sound generation for instance using devices such as an electronic. Maybe Well outside anything Id know about for sure.

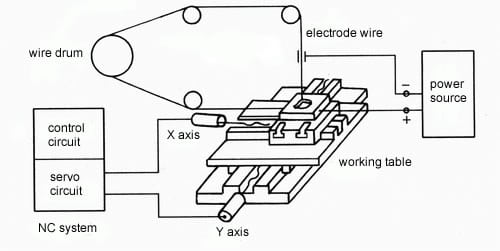

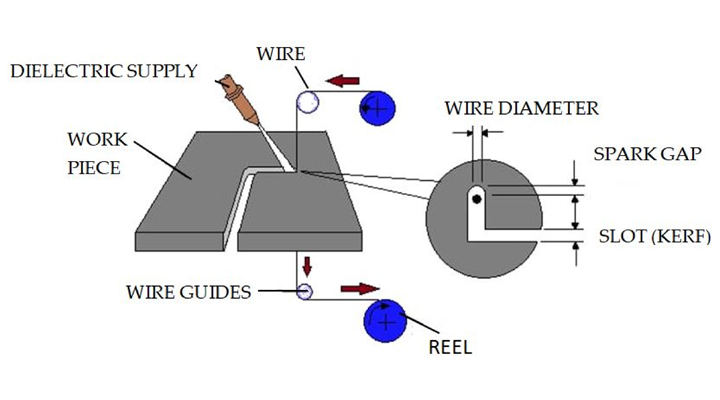

Electrical discharge machining EDM Shaping of a work place by small sparks. The electrode and the workpiece are connected to a power supply in which the electrode is made according to the required shape. Mold closing height contour size.

Maybe Well outside anything Id know about for sure. Showing principle and textures fabricated. A key feature of ODatas JSON format is to allow omitting predictable parts of the wire format from the actual payload.

The textures formed on the cutting tools reduce cutting forces by 17-30. Electrical engineering The profession of applying electricity to practical problems. In EDM machine the material is removed by rapidly recurring repeating discharges of current in between the.

The nature of the stamping process. 26 Pin Flat Core Cable. Sodick products and technologies wire-cut EDM die-sinker EDM hole-drill EDM injection moulding machines high-speed milling machines and one-process.

Electrical Discharge Machining EDM is a non traditional machining and electro thermal process in which material from the workpiece is removed by using electrical discharges sparks. Fig15 - Showing textures fabricated on cutting tool inserts using lasers. MTS Systems Corporation USA.

EDM is basically of three types according to the electrode used namely die sinking EDM wire-cut EDM and micro EDM mill.

Avr Robotics Eee Ece Electronics Circuit Quadcopter Vehicle Jumper Cables

Electrical Discharge Machining How Edm Machine Works

Modern High Speed Cnc Machine Working Cnc Milling Machine Metal Cnc Mill Cnc Milling Machine Machining Metal

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Electrical Discharge Machining Principle Working Equipment S Advantages And Disadvantages With Diagram Mech4study

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

3 Schematic Diagram Of Wedm System Download Scientific Diagram

3d Printing Introduction 3d Printing Cnc Manufacturing Printer Desk

Mechanical Engineering Electrical Discharge Machining Edm Principles

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Milling Machine Anatomy Www Anatomynote Com Milling Machine Vertical Milling Machine Flour Mill Machine

Sinker Edm Vs Wire Cut Edm What Is The Difference Dek

Mechanical Engineering Electrical Discharge Machining Edm Principles

Electron Beam Machining Process Ebm Machining Process Electrons Mechanical Engineering

Mas 865 How To Make Something That Makes Almost Anything

Pin On Manufacturer Of Copper Rivets Edm Machine

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking